Accusharp has manufactured a wide range of high-quality metal cutting tools for various industries for over two decades now. OEMs trust us for our innovative and world-class solutions that are tailored to meet customer requirements. Our products are used in various industries like aerospace engineering, automotive industries, manufacturing units, construction industry, and machining industry

High performance and high-speed Solid Carbide TIP T-Slot Cutter with Solid Carbide Tip for High Productivity and Long Tool Life.

Features

Applications

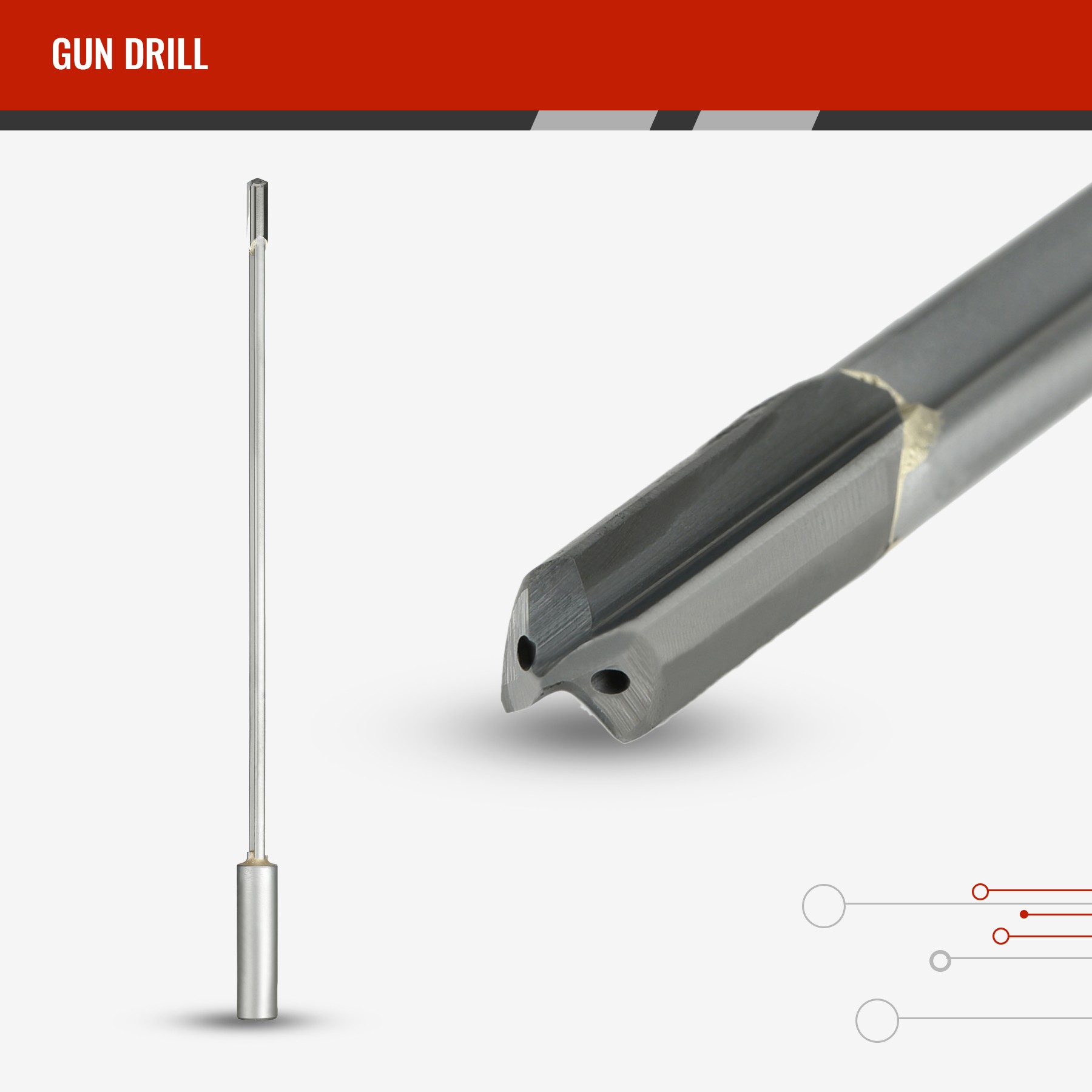

High-accuracy Gun drills are straight fluted drills used for deep drilling.

Features

Applications