Features

Application

Description

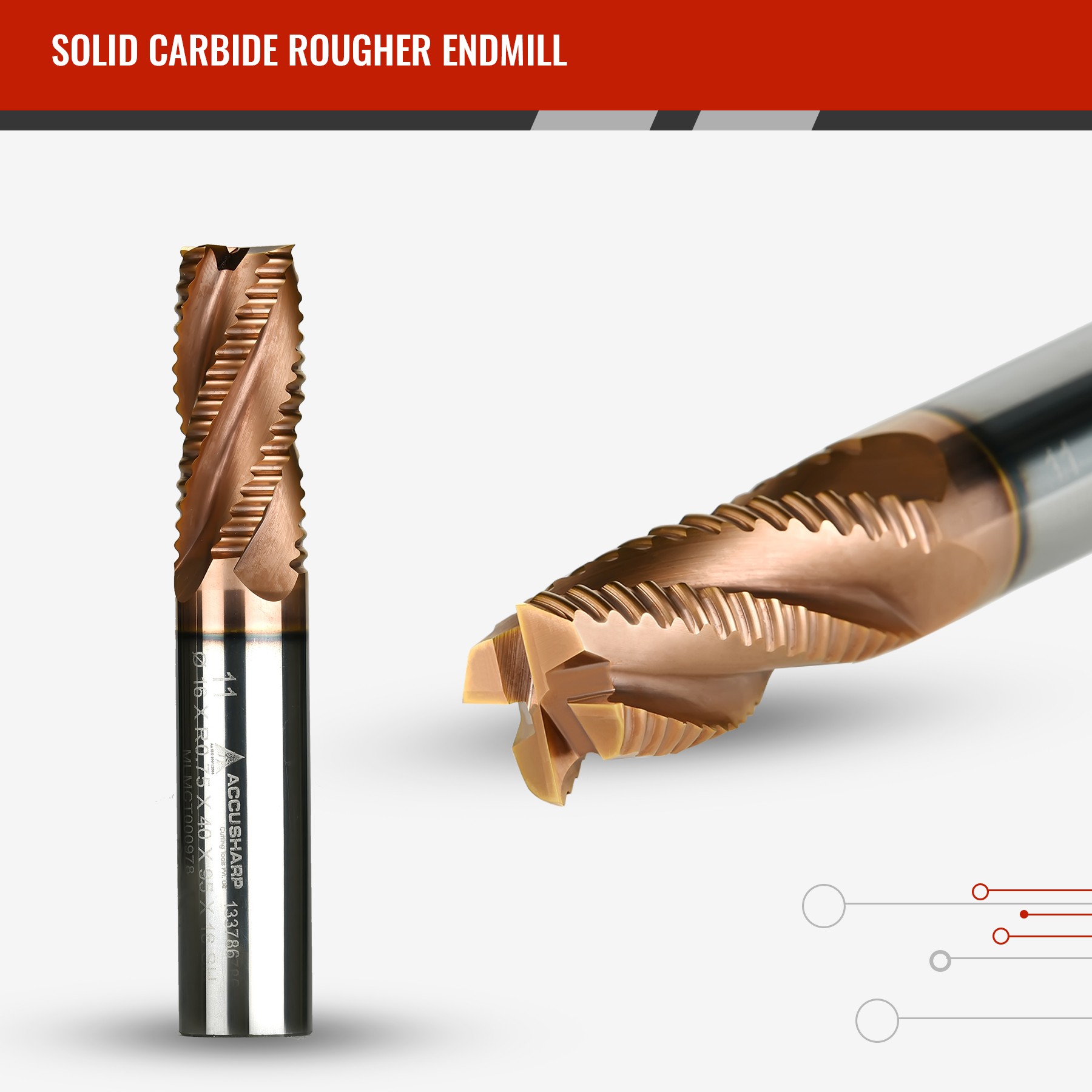

Roughers are manufactured by ACCUSHARP Cutting Tools for a variety of materials and circumstances. Because our rougher end mills have a far higher effective feed per tooth than a typical end mills, we can make deep cuts. In most cases, a 20% reduction in effective horsepower is applied. Chip-breaker cutting edges are used on roughers, and the “peaks” on each cutting edge provide the cutting action, resulting in short fat chips rather than the lengthy stringy chips generated by traditional mills.

ACCUSHARP other types of end mills remove less metal in less time than solid carbide rougher end mills. With less chatter and vibration, our tools can handle heavier cuts at higher speeds. The coarse and fine pitch tooth forms provide good heat dissipation during heavy cutting operations, making the tool particularly useful for cutting high tensile steels.